Short Lead Time for Stainless Steel Liquid Tight Conduit - Polyethylene Tubing for Cable Protection – Weyer

Short Lead Time for Stainless Steel Liquid Tight Conduit - Polyethylene Tubing for Cable Protection – Weyer Detail:

Introduction of Polyethylene Tubing

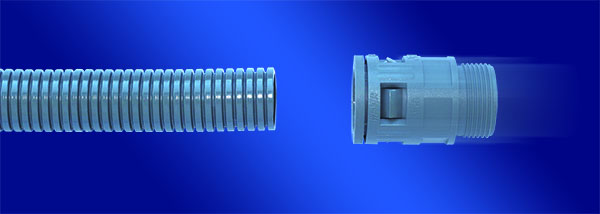

The material of tubing is Polyethylene. It is easy to install and uninstall, extremely save time. It can be applied to machine building, electric equipment, electric control cupboard. The protection degree can reach IP68, it can protect the cable safty. The properties of polyethylene tubing are oil resistant, flexible, low rigidity, glossy surface, free of halogen, phosphor and cadmium passed RoHS.

WY-PE

| Material | Polyethylene PE |

| Color | Grey (RAL 7037), black (RAL 9005), orange(RAL 2009) |

| Temperature Range | Min-50℃, Max80℃, Short-term100℃ |

| Protection degree | IP68 |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Oil resistant, flexible, low rigidity, glossy surface, free of halogen, phosphor and cadmium passed RoHS |

| Applications | Machine building, electric equipment, electric control cupboard |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| article no. | Color | ID×OD | Stat.r | Dyn.r | weight | PU |

| WY-PE | G/B | mm×mm | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-PE-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PE-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PE-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-PE-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-PE-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-PE-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-PE-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PE-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-PE-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-PE-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-PE-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-PE-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

| WY-PE-AD 8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PE-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PE-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-PE-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-PE-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-PE-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-PE-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PE-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-PE-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-PE-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-PE-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-PE-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

| WY-PE/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PE/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PE/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-PE/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-PE/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-PE/S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-PE/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PE/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-PE/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-PE /S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-PE/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-PE/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

WY-FPE

| Material | Polyethylene PE |

| Color | Grey (RAL 7037), black (RAL 9005), orange(RAL 2009) |

| Temperature Range | Min-50℃, Max100℃, Short-term125℃ |

| Protection degree | IP68 |

| Flame-retardant | V0(UL94), according to FMVSS 302:self-extinguishing, type B |

| Properties | Oil resistant, flexible, low rigidity, glossy surface, free of halogen, phosphor and cadmium passed RoHS |

| Applications | Machine building, electric equipment, electric control cupboard |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| article no. | Color | ID×OD | Stat.r | Dyn.r | weight | PU |

| WY-FPE | G/B | mm×mm | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-FPE-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPE-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPE-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-FPE-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-FPE-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-FPE-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-FPE-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-FPE-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-FPE-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-FPE-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-FPE-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-FPE-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

| WY-FPE-AD 8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPE-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPE-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-FPE-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-FPE-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-FPE-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-FPE-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-FPE-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-FPE-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-FPE-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-FPE-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-FPE-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

| WY-FPE/S-AD8.0B | Slit black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPE/S-AD10.0B | Slit black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPE/S-AD13.0B | Slit black | 9.5×13.0 | 20 | 45 | 0.023 | 100 |

| WY-FPE/S-AD15.8B | Slit black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-FPE/S-AD18.5B | Slit black | 14.3×18.5 | 35 | 65 | 0.036 | 50 |

| WY-FPE/S-AD21.2B | Slit black | 17.0×21.2 | 40 | 75 | 0.048 | 50 |

| WY-FPE/S-AD25.5B | Slit black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-FPE/S-AD28.5B | Slit black | 23.0×28.5 | 45 | 100 | 0.066 | 50 |

| WY-FPE/S-AD31.5B | Slit black | 26.0×31.5 | 50 | 110 | 0.083 | 25 |

| WY-FPE/S-AD34.5B | Slit black | 29.0×34.5 | 55 | 120 | 0.09 | 25 |

| WY-FPE/S-AD42.5B | Slit black | 36.0×42.5 | 65 | 150 | 0.136 | 25 |

| WY-FPE/S-AD54.5B | Slit black | 48.0×54.5 | 80 | 190 | 0.186 | 25 |

Note

1. Slit tubing is available, type: WY-PE/S-AD××, WY-FPE/S-AD××.

2. Tubing has three standard colors, grey, black and orange. We can customize it according to the customers’ requirement.

3. We can provide free samples, customers cover the freight.

Flame-retardant grade: You can choose HB or V0 according as per your request

HB(UL94), According to FMVSS 302:<100mm/min. If customers choose HB, the type is WY-PE-AD××.

V0(UL94), According to FMVSS 302: self-extinguishing, type B. If customers choose V0, the type is WY-FPE-AD××.

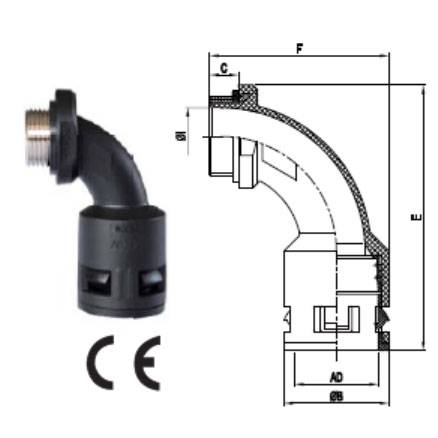

Installation instructions of Polyethylene Tubing

Pushing the tubing into the connector and its assembly is done. Push again until it can not complete its fixing so that it can reach some protection degree.

Normal wave

Ultra flat wave

Non-slit tubing

Slit tubing

Advantages of Flexible Polyamide Conduit

exquisite appearance and excellent craftsmanship

light weight and strong plasticity

long service life

Easy to install and uninstall

High protection degree

Pictures of Corrugated Polyamide Tubing

Application PolyamideTubing: Machine building

Below photos we are sharing for application used in one of our customer in machinery. The cables need to be protected under IP68 or IP69K against the water and dust when coming out of the control box, which can extend the life of cable usage.

Product detail pictures:

Related Product Guide:

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Short Lead Time for Stainless Steel Liquid Tight Conduit - Polyethylene Tubing for Cable Protection – Weyer, The product will supply to all over the world, such as: Maldives, Honduras, Tunisia, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.