Good User Reputation for 2 Corrugated Tubing - Ultra Flat Wave Polypropylene Tubing – Weyer

Good User Reputation for 2 Corrugated Tubing - Ultra Flat Wave Polypropylene Tubing – Weyer Detail:

Introduction of Polypropylene Tubing

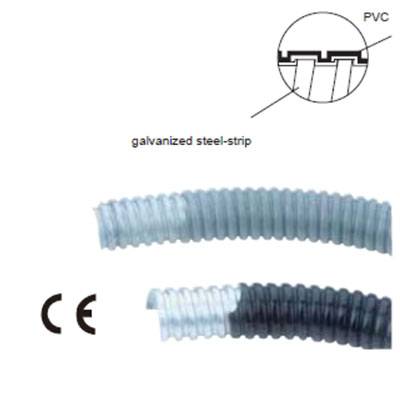

The material of tubing is polypropylene pp. Polypropylene conduit has the characteristics of high hardness, heavy pressure resistance, wear resistance and no deformation, high mechanical strength, slightly poor flexibility, and excellent electrical insulation and mechanical electrical protection. It does not contain halogen, phosphorus, and cadmium, passed RoHS. It also has excellent chemical resistance and corrosion resistance of oil products, so that the entire conduit system can achieve the ultimate protection effect

WY-UFW-PP

| Color | Grey (RAL 7037), black (RAL 9005), |

| Temperature Range | Min-40℃, Max110℃,Short-term130℃ |

| Protection degree | IP68 |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Oil resistant, excellent chemical resistance to acids, alkali and corrosion, high mechanical strength, lack of flexibility, dim surface, free of halogen, phosphor and cadmium, passed RoHS Ultra inner hole, less abrasion to the cables |

| Applications | Machine building, chemical equipment, especially suitable for vehicle industry with frequent vibration |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-UFW-PP | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| *WY-UFW-PP-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-PP-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.013 | 100 |

| WY-UFW-PP-AD13.0B | Black | 9.2×13.0 | 20 | 45 | 0.018 | 100 |

| WY-UFW-PP-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.023 | 100 |

| WY-UFW-PP-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.029 | 50 |

| WY-UFW-PP-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.042 | 50 |

| WY-UFW-PP-AD25.5B | Black | 19.5×25.5 | 42 | 85 | 0.05 | 50 |

| WY-UFW-PP-AD28.5B | Black | 22.2×28.5 | 45 | 100 | 0.058 | 50 |

| WY-UFW-PP-AD31.5B | Black | 25.0×31.5 | 50 | 110 | 0.069 | 25 |

| *WY-UFW-PP-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.072 | 25 |

| *WY-UFW-PP-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.113 | 25 |

| *WY-UFW-PP-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.158 | 25 |

| WY-UFW-PP/S-AD8.0B | slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-PP/S-AD10.0B | slit Black | 6.5×10.0 | 15 | 35 | 0.013 | 100 |

| WY-UFW-PP/S-AD13.0B | slit Black | 9.2×13.0 | 20 | 45 | 0.018 | 100 |

| WY-UFW-PP/S-AD15.8B | slit Black | 12.0×15.8 | 25 | 55 | 0.023 | 100 |

| WY-UFW-PP/S-AD18.5B | slit Black | 14.3×18.5 | 35 | 65 | 0.029 | 50 |

| WY-UFW-PP/S-AD21.2B | slit Black | 16.0×21.2 | 40 | 75 | 0.042 | 50 |

| WY-UFW-PP/S-AD25.5B | slit Black | 19.5×25.5 | 42 | 85 | 0.05 | 50 |

| WY-UFW-PP/S-AD28.5B | slit Black | 22.2×28.5 | 45 | 100 | 0.058 | 50 |

| WY-UFW-PP/S-AD31.5B | slit Black | 25.0×31.5 | 50 | 110 | 0.069 | 25 |

| WY-UFW-PP/S-AD34.5B | slit Black | 29.0×34.5 | 55 | 120 | 0.072 | 25 |

| WY-UFW-PP/S-AD42.5B | slit Black | 36.0×42.5 | 65 | 150 | 0.113 | 25 |

| WY-UFW-PP/S-AD54.5B | slit Black | 48.0×54.5 | 80 | 190 | 0.158 | 25 |

WY-UFW-FPP

| Material | Polypropylene PP |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃, Max125℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V0(UL94) , according to FMVSS 302, self-extinguishing, type B |

| Properties | il resistant, excellent chemical resistance to acids, alkali and corrosion, high mechanical strength, lack of flexibility, dim surface, free of halogen, phosphor and cadmium, passed RoHS Ultra inner hole, less abrasion to the cables |

| Applications | Machine building, chemical equipment, especially suitable for vehicle industry with frequent vibration |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-UFW-FPP | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| *WY-UFW-FPP-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-FPP-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.013 | 100 |

| WY-UFW-FPP-AD13.0B | Black | 9.2×13.0 | 20 | 45 | 0.019 | 100 |

| WY-UFW-FPP-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.024 | 100 |

| WY-UFW-FPP-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.03 | 50 |

| WY-UFW-FPP-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-UFW-FPP-AD25.5B | Black | 19.5×25.5 | 42 | 85 | 0.052 | 50 |

| WY-UFW-FPP-AD28.5B | Black | 22.2×28.5 | 45 | 100 | 0.06 | 50 |

| WY-UFW-FPP-AD31.5B | Black | 25.0×31.5 | 50 | 110 | 0.071 | 25 |

| *WY-UFW-FPP-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.074 | 25 |

| *WY-UFW-FPP-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.116 | 25 |

| *WY-UFW-FPP-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.163 | 25 |

| WY-UFW-FPP/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-FPP/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.013 | 100 |

| WY-UFW-FPP/S-AD13.0B | Slit Black | 9.2×13.0 | 20 | 45 | 0.019 | 100 |

| WY-UFW-FPP/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.024 | 100 |

| WY-UFW-FPP/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.03 | 50 |

| WY-UFW-FPP/S-AD21.2B | Slit Black | 16.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-UFW-FPP/S-AD25.5B | Slit Black | 19.5×25.5 | 42 | 85 | 0.052 | 50 |

| WY-UFW-FPP/S-AD28.5B | Slit Black | 22.2×28.5 | 45 | 100 | 0.06 | 50 |

| WY-UFW-FPP/S-AD31.5B | Slit Black | 25.0×31.5 | 50 | 110 | 0.071 | 25 |

| WY-UFW-FPP/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.074 | 25 |

| WY-UFW-FPP/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.116 | 25 |

| WY-UFW-FPP/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.163 | 25 |

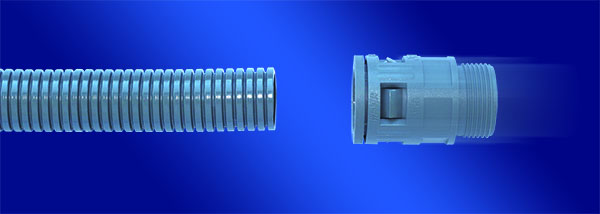

Installation instructions of Polyamide Tubing

Pushing the tubing into the connector and its assembly is done. Push again until it can not complete its fixing so that it can reach some protection degree.

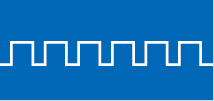

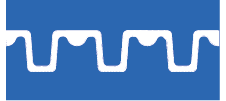

Normal wave

Ultra flat wave

Non-slit tubing

Slit tubing

Advantages of Flexible Polyamide Conduit

The density of polypropylene is low, only 0.91-0.92g / cm3.

High heat resistance.

The texture is relatively hard and the surface hardness is high.

Has a certain brittleness, especially at low temperatures.

High protection degree

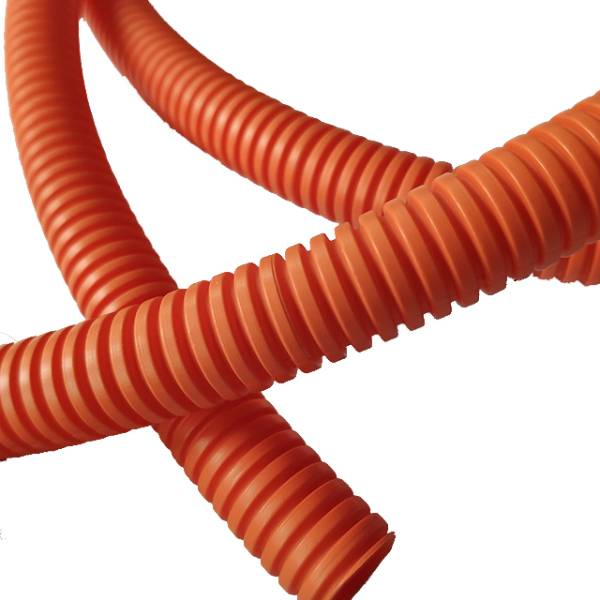

Pictures of Corrugated Polyamide Tubing

Application PolyamideTubing: Machine building

Due to its excellent performance characteristics, plastic corrugated tubing is widely used in jacket tubings and wire tubings of various electrical, mechanical and machine tools in various machinery manufacturing industries. At the same time, the reasonable matching of plastic bellows and various adapters can play a good role in the connection between the mechanical assembly and the machine.

Product detail pictures:

Related Product Guide:

Persisting in "High good quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for Good User Reputation for 2 Corrugated Tubing - Ultra Flat Wave Polypropylene Tubing – Weyer, The product will supply to all over the world, such as: Greece, United States, Liverpool, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.