Good quality Emt To Flex Coupling - Polyamide Corrugated Tubing – Weyer

Good quality Emt To Flex Coupling - Polyamide Corrugated Tubing – Weyer Detail:

Introduction of Polyamide 6 Tubing

Nylon tubing (polyamide), referred to as PA tubing. It is a kind of synthetic fiber, with good physical and chemical and mechanical properties: abrasion resistance, can be used in the condition of sand, iron scraps; smooth surface, reduce resistance, can prevent rust and scale deposition; soft, easy it is curved, easy to install and easy to process. At the same time, it is steel. When a certain shape is needed, it can be made into a variety of shapes like a metal tube, and it does not require complicated equipment and tooling; it can withstand the corrosion of many chemical substances; it has stable dimensions and small permeability; Can be used as an insulator; the service life is very long, even for decades; good temperature resistance, can work in the environment of -40-115 ° C.

WY-PA6

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max125℃,Short-term150℃ |

| Flame-retardant | V2(UL94) |

| Properties | Soft and tough, medium wall thickness, glossy surface, anti-twist, high impact resistance, high mechanical strength, more uniform force than ordinary pitch hose, hose bending ability is stronger. Oil resistance, alkali resistance, weak acid resistance, friction resistance, black resistance to ultraviolet radiation, no halogen, phosphorus, cadmium, through the RoHS test |

| Applications | Mechanical building, heavy equipment, electric factory, underground, electric vehicle building etc. |

| Fit with | WQGD, WQGDM Tubing connector |

Tech Specification

| article no. | Color | ID×OD | Stat.r | Dyn.r | weight | PU |

| WY-PA | G/B | (mm×mm) | mm | mm | (kg/m±10%) | (m/ring) |

| WY-PA6-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-PA6-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.022 | 100 |

| WY-PA6-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-PA6-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.056 | 50 |

| WY-PA6-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.066 | 50 |

| WY-PA6-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.09 | 50 |

| WY-PA6-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.105 | 25 |

| WY-PA6-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.12 | 25 |

| WY-PA6-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.17 | 25 |

| WY-PA6-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.211 | 25 |

| WY-PA6-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-PA6-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.022 | 100 |

| WY-PA6-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-PA6-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.056 | 50 |

| WY-PA6-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.066 | 50 |

| WY-PA6-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.09 | 50 |

| WY-PA6-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.105 | 25 |

| WY-PA6-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.12 | 25 |

| WY-PA6-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.17 | 25 |

| WY-PA6-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.211 | 25 |

| WY-PA6/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-PA6/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.022 | 100 |

| WY-PA6/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-PA6/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6 /S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.056 | 50 |

| WY-PA6/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.066 | 50 |

| WY-PA6/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.09 | 50 |

| WY-PA6/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.105 | 25 |

| WY-PA6/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.12 | 25 |

| WY-PA6/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.17 | 25 |

| WY-PA6/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.211 | 25 |

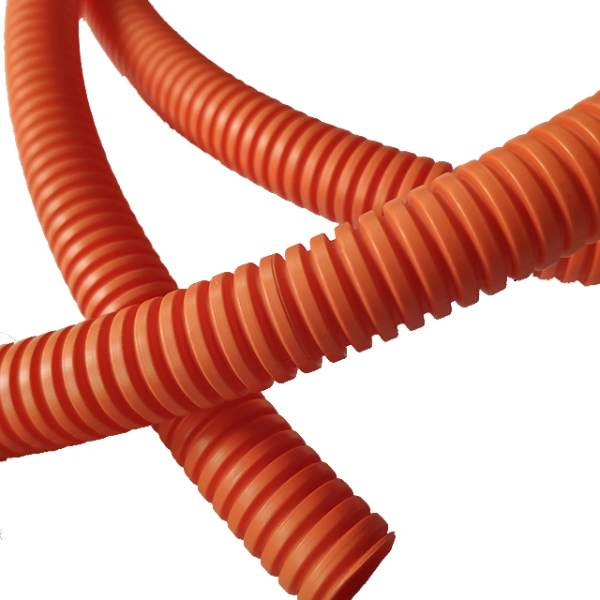

WY-PA6-C

| Material | Polyamide 6 |

| Color | Black (RAL 9005), orange(RAL 2009) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Oil resistance, acid and alkali resistance, good chemical corrosion resistance, good mechanical strength, high cost performance, while meeting the latest automotive industry standards, glossy surface, passed RoHS |

| Applications | It is suitable for car wire harness, elevator industry and situations that need to be quickly threaded |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

WYK-PA6-D

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V0(UL94), according to FMVSS 302 requirements; 100mm/min |

| Properties | Oil resistant, excellent chemical resistance to acids, alkali andcorrosion, high mechanical strength, lack of flexibility, glossy surface, passed RoHS |

| Applications | Machine building, chemical equipment |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

| article no. | Color | ID×OD | Stat.R | Dyn.R | weight | PU |

| WY-PA6-D | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-PA6-D-AD8.0G | Grey | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-D-AD10.0G | Grey | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-D-AD13.0G | Grey | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-D-AD15.8G | Grey | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-D-AD18.5G | Grey | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-D-AD21.2G | Grey | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-D-AD25.5G | Grey | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-D-AD28.5G | Grey | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-D-AD31.5G | Grey | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-D-AD34.5G | Grey | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-D-AD42.5G | Grey | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-D-AD54.5G | Grey | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

| WY-PA6-D-AD8.0B | Black | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-D-AD10.0B | Black | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-D-AD13.0B | Black | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-D-AD15.8B | Black | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-D-AD18.5B | Black | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-D-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-D-AD25.5B | Black | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-D-AD28.5B | Black | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-D-AD31.5B | Black | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-D-AD34.5B | Black | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-D-AD42.5B | Black | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-D-AD54.5B | Black | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

WY-PA6-V2

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005),orange(RAL 2009) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V2 (UL94), according to FMVSS 302: self-extinguishing, type B |

| Properties | Flexible and excellent tenacity, glossy surface, wind resistanthigh mechanical strength, resistant to oil, acid and solvents, anti-friction, black tubings UV-resistant, self-extinguishing, medium wall thickness, free of halogen, phosphor and cadmium, passed RoHS |

| Applications | Machine tool, mechanical building, electric insulation protection, underground, electric vehicle and air-conditioner equipment etc. |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.r | Dyn.r | Weight | PU |

| WY-PA | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-PA6-V2-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6-V2-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.02 | 100 |

| WY-PA6-V2-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.025 | 100 |

| WY-PA6-V2-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.036 | 100 |

| WY-PA6-V2-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6-V2-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.058 | 50 |

| WY-PA6-V2-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PA6-V2-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.092 | 50 |

| WY-PA6-V2-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.107 | 25 |

| WY-PA6-V2-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.122 | 25 |

| WY-PA6-V2-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.175 | 25 |

| WY-PA6-V2-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.245 | 25 |

| WY-PA6-V2-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6-V2-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.02 | 100 |

| WY-PA6-V2-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.025 | 100 |

| WY-PA6-V2-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.036 | 100 |

| WY-PA6-V2-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6-V2-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.058 | 50 |

| WY-PA6-V2-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PA6-V2-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.092 | 50 |

| WY-PA6-V2-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.107 | 25 |

| WY-PA6-V2-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.122 | 25 |

| WY-PA6-V2-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.175 | 25 |

| WY-PA6-V2-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.245 | 25 |

| WY-PA6-V2/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PA6-V2 /S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.02 | 100 |

| WY-PA6-V2/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.025 | 100 |

| WY-PA6-V2/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.036 | 100 |

| WY-PA6-V2/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.05 | 50 |

| WY-PA6-V2/S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.058 | 50 |

| WY-PA6-V2/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-PA6-V2/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.092 | 50 |

| WY-PA6-V2/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.107 | 25 |

| WY-PA6-V2/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.122 | 25 |

| WY-PA6-V2/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.175 | 25 |

| WY-PA6-V2/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.245 | 25 |

WY-PA6-V2-D

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-PA-V0-D | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-PA6-V0-D-AD8.0G | Grey | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-V0-D-AD10.0G | Grey | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-V0-D-AD13.0G | Grey | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-V0-D-AD15.8G | Grey | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-V0-D-AD18.5G | Grey | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-V0-D-AD21.2G | Grey | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-V0-D-AD25.5G | Grey | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-V0-D-AD28.5G | Grey | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-V0-D-AD31.5G | Grey | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-V0-D-AD34.5G | Grey | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-V0-D-AD42.5G | Grey | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-V0-D-AD54.5G | Grey | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

| WY-PA6-V0-D-AD8.0B | Black | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-V0-D-AD10.0B | Black | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-V0-D-AD13.0B | Black | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-V0-D-AD15.8B | Black | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-V0-D-AD18.5B | Black | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-V0-D-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-V0-D-AD25.5B | Black | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-V0-D-AD28.5B | Black | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-V0-D-AD31.5B | Black | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-V0-D-AD34.5B | Black | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-V0-D-AD42.5B | Black | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-V0-D-AD54.5B | Black | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

WY-PA6-V0-C

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V2 (UL94), according to FMVSS 302: self-extinguishing, type B |

| Properties | Flexible and excellent tenacity, glossy surface, wind resistanthigh mechanical strength, resistant to oil, acid and solvents, anti-friction, black tubings UV-resistant, self-extinguishing, medium wall thickness, free of halogen, phosphor and cadmium, passed RoHS |

| Applications | Machine tool, mechanical building, electric insulation protection, underground, electric vehicle and air-conditioner equipment etc. |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

WY-PA6-V0-D

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max125℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V0 (UL94), according to FMVSS 302: self-extinguishing, Type B |

| Properties | Flexible and excellent tenacity, glossy surface, anti-friction, wind resistant, high mechanical strength, resistant to oil, acid and solvents. black tubings UV-resistant, self-extinguishing,high grade of safety, free of halogen, phosphor and cadmium, medium wall thickness, passed RoHS. We have got railway certificates of Japan, France and Germany |

| Applications | Mechanical building,electric insulation protection, underground, electric vehicle and air-conditioner equipment etc. |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-PA-V0-D | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| WY-PA6-V0-D-AD8.0G | Grey | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-V0-D-AD10.0G | Grey | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-V0-D-AD13.0G | Grey | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-V0-D-AD15.8G | Grey | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-V0-D-AD18.5G | Grey | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-V0-D-AD21.2G | Grey | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-V0-D-AD25.5G | Grey | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-V0-D-AD28.5G | Grey | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-V0-D-AD31.5G | Grey | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-V0-D-AD34.5G | Grey | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-V0-D-AD42.5G | Grey | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-V0-D-AD54.5G | Grey | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

| WY-PA6-V0-D-AD8.0B | Black | 5.2×8.1 | 12 | 30 | 0.012 | 200 |

| WY-PA6-V0-D-AD10.0B | Black | 6.0×10.0 | 15 | 35 | 0.029 | 100 |

| WY-PA6-V0-D-AD13.0B | Black | 9×13.0 | 20 | 45 | 0.031 | 100 |

| WY-PA6-V0-D-AD15.8B | Black | 11.5×15.8 | 25 | 55 | 0.053 | 100 |

| WY-PA6-V0-D-AD18.5B | Black | 13.8×18.5 | 35 | 65 | 0.078 | 50 |

| WY-PA6-V0-D-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.084 | 50 |

| WY-PA6-V0-D-AD25.5B | Black | 20.5×25.5 | 42 | 85 | 0.099 | 50 |

| WY-PA6-V0-D-AD28.5B | Black | 22.5×28.5 | 45 | 100 | 0.13 | 50 |

| WY-PA6-V0-D-AD31.5B | Black | 25.5×31.5 | 50 | 110 | 0.151 | 25 |

| WY-PA6-V0-D-AD34.5B | Black | 28.5×34.5 | 55 | 120 | 0.168 | 25 |

| WY-PA6-V0-D-AD42.5B | Black | 35.5×42.5 | 65 | 150 | 0.253 | 25 |

| WY-PA6-V0-D-AD54.5B | Black | 47.5×54.5 | 80 | 190 | 0.306 | 25 |

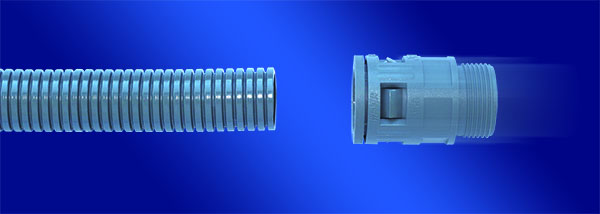

Installation instructions of Polyamide Tubing

Pushing the tubing into the connector and its assembly is done. Push again until it can not complete its fixing so that it can reach some protection degree.

Normal wave

Ultra flat wave

Non-slit tubing

Slit tubing

Advantages of Flexible Polyamide Conduit

1. High mechanical strength, good toughness, high tensile and compressive strength.

2. The fatigue resistance is outstanding, and the parts can still maintain the original mechanical strength after repeated bending.

3. High softening point and heat resistance.

4. The surface is smooth, the friction coefficient is small, and it is wear-resistant.

5. Corrosion resistance.

6. Self-extinguishing, non-toxic, odorless.

7. Excellent electrical properties, good electrical insulation.

Pictures of Corrugated Polyamide Tubing

Application PolyamideTubing: Machine building

Below photos we are sharing for application used in one of our customer in machinery. The cables need to be protected under IP68 or IP69K against the water and dust when coming out of the control box, which can extend the life of cable usage.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Good quality Emt To Flex Coupling - Polyamide Corrugated Tubing – Weyer, The product will supply to all over the world, such as: Provence, Monaco, Kuwait, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.