Flame Retardant Corrugated Polypropylene Conduit

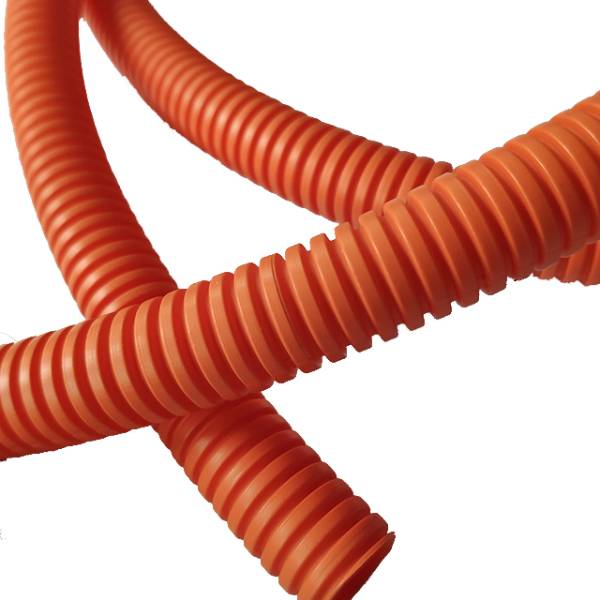

Introduction of Polypropylene Tubing

The material of tubing is polypropylene pp. Polypropylene conduit has the characteristics of high hardness, heavy pressure resistance, wear resistance and no deformation, high mechanical strength, slightly poor flexibility, and excellent electrical insulation and mechanical electrical protection. It does not contain halogen, phosphorus, and cadmium, passed RoHS. It also has excellent chemical resistance and corrosion resistance of oil products, so that the entire conduit system can achieve the ultimate protection effect.

WY-PP

| Material | Polypropylene PP |

| Color | Grey (RAL 7037), black (RAL 9005),orange(RAL 2009) |

| Temperature Range | Min-40℃, Max110℃,Short-term120℃ |

| Protection degree | IP68 |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Oil resistant, excellent chemical resistance to acids, alkali and corrosion, high mechanical strength, lack of flexibility, dim surface, free of halogen, phosphor and cadmium, passed RoHS |

| Applications | Machine building, chemical equipment |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| article no. | Color | ID×OD | Stat.r | Dyn.r | weight | PU |

| WY-PP | G/B | (mm×mm) | mm | mm | (kg/m±10%) | (m/ring) |

| WY-PP-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PP-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PP-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-PP-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-PP-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-PP-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-PP-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-PP-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-PP-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-PP-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-PP-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-PP-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

| WY-PP-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PP-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PP-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-PP-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-PP-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-PP-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-PP-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-PP-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-PP-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-PP-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-PP-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-PP-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

| WY-PP/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-PP/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-PP/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-PP/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-PP/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-PP/S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-PP/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-PP/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-PP/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-PP/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-PP/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-PP/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

WY-FPP

| Material | Polypropylene PP |

| Color | Grey (RAL 7037), black (RAL 9005),orange(RAL 2009) |

| Temperature Range | Min-40℃, Max125℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V0(UL94), self-extinguishing, A level, according to FMVSS 302requirements, according to GB/T2408 standard, flame retardant to V0 level |

| Properties | Oil-resistant, acid-base resistant, excellent chemical corrosionresistance, low strength, lack of softness, tarnished surface, passed RoHS test through QC/T29106 thermal aging 3000h, thermal aging 240h |

| Applications | Machine building, chemical equipment,Car wire harness |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| article no. | Color | ID×OD | Stat.r | Dyn.r | weight | PU |

| WY-FPP | G/B | (mm×mm) | mm | mm | (kg/m±10%) | (m/ring) |

| WY-FPP-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPP-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPP-AD13.0G | Grey | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-FPP-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-FPP-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-FPP-AD21.2G | Grey | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-FPP-AD25.5G | Grey | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-FPP-AD28.5G | Grey | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-FPP-AD31.5G | Grey | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-FPP-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-FPP-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-FPP-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

| WY-FPP-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPP-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPP-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-FPP-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-FPP-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-FPP-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-FPP-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-FPP-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-FPP-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-FPP-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-FPP-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-FPP-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

| WY-FPP/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-FPP/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-FPP/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-FPP/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-FPP/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-FPP/S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.043 | 50 |

| WY-FPP/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.052 | 50 |

| WY-FPP/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-FPP/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.073 | 25 |

| WY-FPP/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.077 | 25 |

| WY-FPP/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.11 | 25 |

| WY-FPP/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

WY-FPP-C

| Material | Polypropylene PP |

| Color | Grey (RAL 7037), black (RAL 9005),orange(RAL 2009) |

| Temperature Range | Min-40℃, Max125℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V0(UL94), self-extinguishing, A level, according to FMVSS 302requirements, according to GB/T2408 standard, flame retardant to V0 level |

| Characteristics | Oil resistance, acid and alkali resistance, good chemical corrosion resistance, low strength, lack of flexibility, high cost performance, while meeting the latest automotive industry standards, dim surface, passed RoHS, passed the thermal aging test acc. to QC/T29106: 3000h, short time 240h |

| Applications | It is suitable for car wire harness, elevator industry and situations that need to be quickly threaded |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

WYK-PA6-V2-D

| Material | Polyamide 6 |

| Color | Black (RAL 9005) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | V2(UL94), according to FMVSS 302: self-extinguish, Type B |

| Properties | Soft and tough, medium wall thickness, glossy surface, anti-twist, high impact resistance, high mechanical strength, more uniform force than ordinary pitch hose, hose bending ability is stronger. Oil resistance, alkali resistance, weak acid resistance, friction resistance, black resistance to ultraviolet radiation, no halogen, phosphorus, cadmium, through the RoHS test |

| Applications | Machine tool, mechanical building, electric insulation protection, underground, electric vehicle and air-conditioner equipment etc. |

| Fit with | WQGD, WQGDM tubing connector |

Tech Specification

WY-HTPP

| Material | High temperature resistant Polypropylene |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃, Max125℃,Short-term150℃ |

| Protection degree | IP68 |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Oil resistant, excellent chemical resistance to acids, alkalies and corrosion, high mechanical strength, lack of flexibility, dim surface, free of halogen, phosphor and cadmium, passed RoHS |

| Applications | Machine building, chemical equipment |

| Fit with | All tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-HTPP | G/B | (mm×mm) | mm | mm | (kg/m±10%) | (m/ring) |

| WY-HTPP-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-HTPP-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-HTPP-AD13.0B | Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-HTPP-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-HTPP-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-HTPP-AD21.2B | Black | 17.0×21.2 | 40 | 75 | 0.047 | 50 |

| WY-HTPP-AD25.5B | Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-HTPP-AD28.5B | Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-HTPP-AD31.5B | Black | 26.0×31.5 | 50 | 110 | 0.077 | 25 |

| WY-HTPP-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.08 | 25 |

| WY-HTPP-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.125 | 25 |

| WY-HTPP-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

| WY-HTPP/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-HTPP/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-HTPP/S-AD13.0B | Slit Black | 9.5×13.0 | 20 | 45 | 0.02 | 100 |

| WY-HTPP/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.026 | 100 |

| WY-HTPP/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.032 | 50 |

| WY-HTPP/S-AD21.2B | Slit Black | 17.0×21.2 | 40 | 75 | 0.047 | 50 |

| WY-HTPP/S-AD25.5B | Slit Black | 21.0×25.5 | 42 | 85 | 0.056 | 50 |

| WY-HTPP/S-AD28.5B | Slit Black | 23.0×28.5 | 45 | 100 | 0.064 | 50 |

| WY-HTPP/S-AD31.5B | Slit Black | 26.0×31.5 | 50 | 110 | 0.077 | 25 |

| WY-HTPP/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.08 | 25 |

| WY-HTPP/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.125 | 25 |

| WY-HTPP/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.175 | 25 |

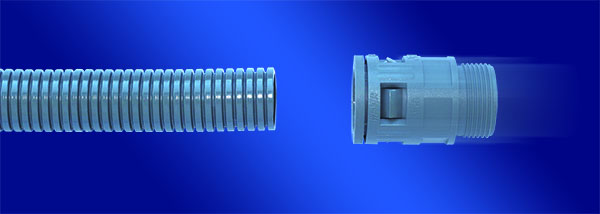

Installation instructions of Polyamide Tubing

Pushing the tubing into the connector and its assembly is done. Push again until it can not complete its fixing so that it can reach some protection degree.

Normal wave

Ultra flat wave

Non-slit tubing

Slit tubing

Advantages of Flexible Polyamide Conduit

The density of polypropylene is low, only 0.91-0.92g / cm3.

High heat resistance.

The texture is relatively hard and the surface hardness is high.

Has a certain brittleness, especially at low temperatures.

High protection degree

Pictures of Corrugated Polyamide Tubing

Application PolyamideTubing: Machine building

Due to its excellent performance characteristics, plastic corrugated tubing is widely used in jacket tubings and wire tubings of various electrical, mechanical and machine tools in various machinery manufacturing industries. At the same time, the reasonable matching of plastic bellows and various adapters can play a good role in the connection between the mechanical assembly and the machine.