Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer

Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer Detail:

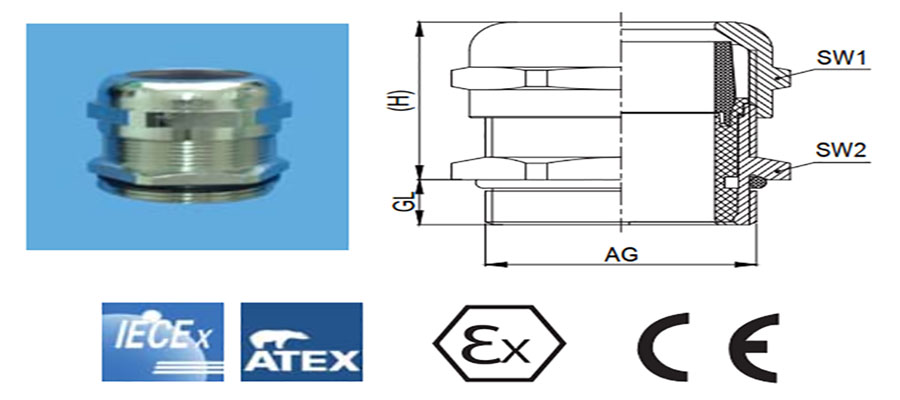

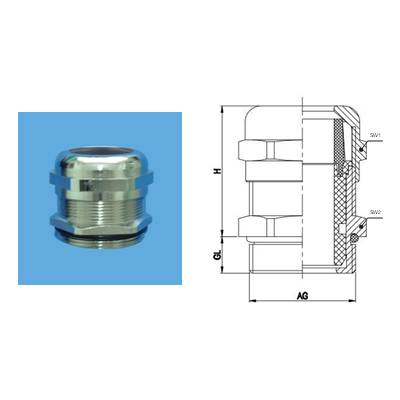

Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread)

Introduction

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.We can provide you with metal cable glands made of nickel-plated brass (Order No.: HSM-EX) and stainless steel (Order No.: HSMS-EX).

| Material: | Body: nickel-plated brass; seal: polyamide; sealing: modified rubber |

| Temperature Range: | Min -40℃, Max 100℃, Short-term 120℃ |

| Protection degree: | IP68(IEC60529) with suitable O-ring within specified clamping range |

| Properties: | Resistance to vibration and impact, in accordance with IEC-60077-1999. |

| Applications: | Machine building, electric equipment, electric control cupboard |

| Certifications: | CE, RoHS, Exe II Gb, IECEx, ATEX. |

Specification

(Please contact us for more information if you need other sizes not included in the following list.)

|

Explosion-proof Nickel-plated brass cable gland (Metric thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-M12 |

M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-M16-H |

M16×1.5 |

3~6.5 |

16 |

7 |

20 |

14/18 |

75 |

|

HSM-EX-M16 |

M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

|

HSM-EX-M16-D |

M16×1.5 |

5~10 |

16 |

7 |

22.5 |

20/20 |

32 |

|

HSM-EX-M18 |

M18×1.5 |

5~10 |

18 |

7 |

22.5 |

20/20 |

50 |

|

HSM-EX-M20-H |

M20×1.5 |

5~10 |

20 |

7 |

22.5 |

20/22 |

32 |

|

HSM-EX-M20 |

M20×1.5 |

6~12 |

20 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-M20-D |

M20×1.5 |

8~14 |

20 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M22 |

M22×1.5 |

8~14 |

22 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M24-H |

M24×1.5 |

6~12 |

24 |

7 |

23.5 |

24/27 |

18 |

|

HSM-EX-M24 |

M24×1.5 |

8~14 |

24 |

7 |

23 |

24/27 |

18 |

|

HSM-EX-M25-H |

M25×1.5 |

8~14 |

25 |

7 |

23 |

24/28 |

18 |

|

HSM-EX-M25 |

M25×1.5 |

10~16 |

25 |

7 |

24.5 |

28/28 |

18 |

|

HSM-EX-M25-D |

M25×1.5 |

13~18 |

25 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-M27-H |

M27×2.0 |

10~16 |

27 |

8 |

24.5 |

28/30 |

18 |

|

HSM-EX-M27 |

M27×2.0 |

13~18 |

27 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-M30-H |

M30×2.0 |

10~16 |

30 |

8 |

24.5 |

28/34 |

18 |

|

HSM-EX-M30 |

M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

|

HSM-EX-M32-H |

M32×1.5 |

13~18 |

32 |

8 |

26 |

30/36 |

8 |

|

HSM-EX-M32 |

M32×1.5 |

15~22 |

32 |

8 |

28 |

36/36 |

18 |

|

HSM-EX-M32-D |

M32×1.5 |

18~25 |

32 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M33 |

M33×2.0 |

18~25 |

33 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M36-H |

M36×2.0 |

15~22 |

36 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-M36 |

M36×2.0 |

18~25 |

36 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-M40-H |

M40×1.5 |

18~25 |

40 |

9 |

33.5 |

40/45 |

8 |

|

HSM-EX-M40 |

M40×1.5 |

22~30 |

40 |

9 |

35.5 |

45/45 |

8 |

|

HSM-EX-M40-D |

M40×1.5 |

22~32 |

40 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M42 |

M42×2.0 |

22~32 |

42 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M48 |

M48×2.0 |

22~32 |

48 |

9 |

38.5 |

50/52 |

4 |

|

HSM-EX-M50 |

M50×1.5 |

30~38 |

50 |

9 |

40 |

58/55 |

4 |

|

HSM-EX-M56 |

M56×2.0 |

30~38 |

56 |

9 |

40 |

58/60 |

2 |

|

HSM-EX-M60 |

M60×2.0 |

37~44 |

60 |

10 |

41 |

65/65 |

2 |

|

HSM-EX-M63 |

M63×1.5 |

37~44 |

63 |

10 |

41 |

65/70 |

2 |

|

HSM-EX-M63-D |

M63×1.5 |

42~53 |

63 |

10 |

44.5 |

75/75 |

2 |

|

HSM-EX-M64 |

M64×2.0 |

37~44 |

64 |

10 |

41 |

65/70 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07 |

PG7 |

3~6.5 |

12.5 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-P09-H |

PG9 |

3~6.5 |

15.2 |

7 |

20 |

14/17 |

75 |

|

HSM-EX-P09 |

PG9 |

4~8 |

15.2 |

7 |

21 |

17/17 |

75 |

|

HSM-EX-P11 |

PG11 |

5~10 |

18.6 |

7 |

22.5 |

20/22 |

75 |

|

HSM-EX-P13.5-H |

PG13.5 |

5~10 |

20.4 |

7 |

22.5 |

22/22 |

32 |

|

HSM-EX-P13.5 |

PG13.5 |

6~12 |

20.4 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-H |

PG16 |

6~12 |

22.5 |

7 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16 |

PG16 |

8~14 |

22.5 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-P21-H |

PG21 |

10~16 |

28.3 |

7 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21 |

PG21 |

13~18 |

28.3 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-P29-H |

PG29 |

15~22 |

37 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-P29 |

PG29 |

18~25 |

37 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-P36 |

PG36 |

22~32 |

47 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-P42 |

PG42 |

30~38 |

54 |

9 |

40 |

58/58 |

2 |

|

HSM-EX-P48 |

PG48 |

37~44 |

59.3 |

10 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread: lengthened thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07-L |

PG7 |

3~6.5 |

12.5 |

10 |

19 |

14/14 |

50 |

|

HSM-EX-P09-HL |

PG9 |

3~6.5 |

15.2 |

10 |

20 |

14/17 |

50 |

|

HSM-EX-P09-L |

PG9 |

4~8 |

15.2 |

10 |

21 |

17/17 |

50 |

|

HSM-EX-P11-L |

PG11 |

5~10 |

18.6 |

10 |

22.5 |

20/20 |

50 |

|

HSM-EX-P13.5-HL |

PG13.5 |

5~10 |

20.4 |

10 |

22.5 |

20/22 |

32 |

|

HSM-EX-P13.5-L |

PG13.5 |

6~12 |

20.4 |

10 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-HL |

PG16 |

6~12 |

22.5 |

10 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16-L |

PG16 |

8~14 |

22.5 |

10 |

23 |

24/24 |

32 |

|

HSM-EX-P21-HL |

PG21 |

10~16 |

28.3 |

12 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21-L |

PG21 |

13~18 |

28.3 |

12 |

26 |

30/30 |

18 |

|

HSM-EX-P29-HL |

PG29 |

15~22 |

37 |

12 |

28 |

36/40 |

8 |

|

HSM-EX-P29-L |

PG29 |

18~25 |

37 |

12 |

33 |

40/40 |

8 |

|

HSM-EX-P36-L |

PG36 |

22~32 |

47 |

15 |

38.5 |

50/50 |

2 |

|

HSM-EX-P42-L |

PG42 |

30~38 |

54 |

15 |

40 |

58/58 |

2 |

|

HSM-EX-P48-L |

PG48 |

37~44 |

59.3 |

15 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (G thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-G3/8 |

G3/8″ |

4~8 |

16.66 |

8 |

21 |

17/20 |

32 |

|

HSM-EX-G1/2-H |

G1/2″ |

5~10 |

20.99 |

8 |

22.5 |

20/24 |

32 |

|

HSM-EX-G1/2 |

G1/2″ |

6~12 |

20.99 |

8 |

23.5 |

22/24 |

32 |

|

HSM-EX-G1/2-D |

G1/2″ |

8~14 |

20.99 |

8 |

23.5 |

24/24 |

32 |

|

HSM-EX-G3/4-TH |

G3/4″ |

6~12 |

26.44 |

8 |

23.5 |

22/30 |

18 |

|

HSM-EX-G3/4-H |

G3/4″ |

8~14 |

26.44 |

8 |

23.5 |

24/30 |

18 |

|

HSM-EX-G3/4 |

G3/4″ |

13~18 |

26.44 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-G1 |

G1″ |

18~25 |

33.24 |

9 |

33 |

40/40 |

8 |

|

HSM-EX-G1 1/4 |

G1 1/4″ |

22~32 |

41.91 |

10 |

38.5 |

50/50 |

4 |

|

HSM-EX-G1 1/2 |

G1 1/2″ |

30~38 |

47.8 |

10 |

40 |

58/55 |

2 |

|

HSM-EX-G2 |

G2″ |

37~44 |

59.61 |

11 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (NPT thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-N3/8 |

NPT3/8 |

4~8 |

16.65 |

16 |

21 |

17/20 |

32 |

|

HSM-EX-N1/2-H |

NPT1/2″ |

5~10 |

21.85 |

20 |

22.5 |

20/23 |

32 |

|

HSM-EX-N1/2 |

NPT1/2″ |

6~12 |

21.85 |

20 |

23.5 |

22/23 |

32 |

|

HSM-EX-N1/2-D |

NPT1/2″ |

8~14 |

21.85 |

20 |

23.5 |

24/24 |

32 |

|

HSM-EX-N3/4-TH |

NPT3/4″ |

6~12 |

26.3 |

21 |

23.5 |

22/30 |

18 |

|

HSM-EX-N3/4-H |

NPT3/4″ |

8~14 |

26.3 |

21 |

23 |

24/30 |

18 |

|

HSM-EX-N3/4 |

NPT3/4″ |

13~18 |

26.3 |

21 |

26 |

30/30 |

18 |

|

HSM-EX-N1 |

NPT1″ |

18~25 |

33.15 |

26 |

33 |

40/40 |

8 |

|

HSM-EX-N1 1/4 |

NPT1 1/4″ |

22~32 |

41.85 |

26 |

38.5 |

50/50 |

4 |

|

HSM-EX-N1 1/2 |

NPT1 1/2″ |

30~38 |

47.75 |

27 |

40 |

58/55 |

2 |

|

HSM-EX-N2 |

NPT2″ |

37~44 |

59.55 |

27 |

41 |

65/65 |

2 |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Factory Supply Openable T-Distributor for corrugated conduit - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer, The product will supply to all over the world, such as: Afghanistan, Sierra Leone, Surabaya, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.