EX Metal Cable Gland

Introduction of EX Metal Cable Gland

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.

We also can provie EX stainless steel cable gland. Such as SUS304, SUS316L.

|

Material: |

Body: nickel-plated brass Seal: Polyamide, Sealing:modified rubber |

|

Temperature Range: |

Min -40℃,Max 100℃,Short-term 120℃ |

|

Protection degree: |

within the clamping range, its protection degree can reach IP68 |

|

Properties: |

succeed in the experiment of IEC-60077-1999 resistance to vibration and impact, passed RoHS |

|

EX degree:

Certifications: |

EX eb IIC Gb Ex tb IIIC Db Certificate NO.: TUV 17ATEX 8015X IECEx TUR 17.0009X CE, RoHS, ATEX, IECEx

|

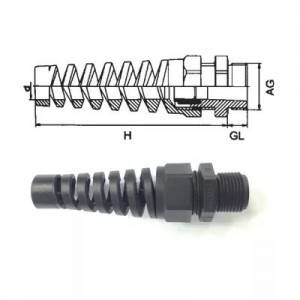

Specification:

(Please contact us for more information if you need other sizes not included in the following list.)

| Article no. | Thread | Clamping range | AG | GL |

(H) |

SW1/SW2 | Packet |

| Dimension |

mm |

mm |

mm | mm |

mm |

units | |

| HSM-EX-M12 | M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

| HSM-EX-M16-H | M16×1.5 |

3~6.5 |

16 |

7 |

20 |

14/18 |

75 |

| HSM-EX-M16 | M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

| HSM-EX-M16-D | M16×1.5 |

5~10 |

16 |

7 |

22.5 | 20/20 |

50 |

| HSM-EX-M18 | M18×1.5 |

5~10 |

18 |

7 |

22.5 | 20/20 |

50 |

| HSM-EX-M20-H | M20×1.5 |

5~10 |

20 |

7 |

22.5 | 20/22 |

32 |

| HSM-EX-M20 | M20×1.5 |

6~12 |

20 |

7 |

23.5 | 22/22 |

32 |

| HSM-EX-M20-D | M20×1.5 |

8~14 |

20 |

7 |

23 |

24/24 |

32 |

| HSM-EX-M22 | M22×1.5 |

8~14 |

22 |

7 |

23 |

24/24 |

32 |

| HSM-EX-M24-H | M24×1.5 |

6~12 |

24 |

7 |

23.5 | 22/28 |

18 |

| HSM-EX-M24 | M24×1.5 |

8~14 |

24 |

7 |

23 |

24/27 |

18 |

| HSM-EX-M25-H | M25×1.5 |

8~14 |

25 |

7 |

23 |

24/28 |

18 |

| HSM-EX-M25 | M25×1.5 |

10~16 |

25 |

7 |

24.5 | 28/28 |

18 |

| HSM-EX-M25-D | M25×1.5 |

13~18 |

25 |

7 |

26 |

30/30 |

18 |

| HSM-EX-M27-H | M27×2.0 |

10~16 |

27 |

8 |

24.5 | 28/30 |

18 |

| HSM-EX-M27 | M27×2.0 |

13~18 |

27 |

8 |

26 |

30/30 |

18 |

| HSM-EX-M30-H | M30×2.0 |

10~16 |

30 |

8 |

24.5 | 28/34 |

18 |

| HSM-EX-M30 | M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

| HSM-EX-M32-H | M32×1.5 |

13~18 |

32 |

8 |

26 |

30/36 |

18 |

| HSM-EX-M32 | M32×1.5 |

15~22 |

32 |

8 |

28 |

36/36 |

18 |

| HSM-EX-M32-D | M32×1.5 |

18~25 |

32 |

8 |

33 |

40/38 |

8 |

| HSM-EX-M33 | M33×2.0 |

18~25 |

33 |

8 |

33 |

40/38 |

8 |

| HSM-EX-M36-H | M36×2.0 |

15~22 |

36 |

8 |

28 |

36/40 |

8 |

| HSM-EX-M36 | M36×2.0 |

18~25 |

36 |

8 |

33 |

40/40 |

8 |

| HSM-EX-M40-H | M40×1.5 |

18~25 |

40 |

9 |

33.5 | 40/45 |

8 |

| HSM-EX-M40 | M40×1.5 |

22~30 |

40 |

9 |

35.5 | 45/45 |

8 |

| HSM-EX-M40-D | M40×1.5 |

22~32 |

40 |

9 |

38.5 | 50/50 |

4 |

| HSM-EX-M42 | M42×2.0 |

22~32 |

42 |

9 |

38.5 | 50/50 |

4 |

| HSM-EX-M48 | M48×2.0 |

22~32 |

48 |

9 |

38.5 | 50/52 |

4 |

| HSM-EX-M50 | M50×1.5 |

30~38 |

50 |

9 |

40 |

58/55 |

4 |

| HSM-EX-M56 | M56×2.0 |

30~38 |

56 |

9 |

40 |

58/60 |

2 |

| HSM-EX-M60 | M60×2.0 |

37~44 |

60 |

10 |

41 |

65/65 |

2 |

| HSM-EX-M63 | M63×1.5 |

37~44 |

63 |

10 |

41 |

65/70 |

2 |

| HSM-EX-M63-D | M63×1.5 |

42~53 |

63 |

10 |

44.5 | 75/75 |

2 |

| HSM-EX-M64 | M64×2.0 |

37~44 |

64 |

10 |

41 |

65/70 |

2 |