EMC Cable Gland (Metric/Pg thread)

EMC Cable Gland (Metric/Pg thread)

Introduction

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.We can provide you with EMC cable glands made of nickel-plated brass (Order No.: HSM-EMV), stainless steel (Order No.: HSMS-EMV) and aluminum (Order No.: HSMAL-EMV).

| Material: | Body: nickel-plated brass; seal: polyamide; sealing: modified rubber |

| Temperature Range: | Min -40℃, Max 100℃, Short-term 120℃ |

| Protection degree: | IP68(IEC60529) with suitable O-ring within specified clamping range |

| Properties: | Resistance to vibration and impact, in accordance with IEC-60077-1999. |

| Applications: | Machine building, electric equipment, electric control cupboard |

| Certifications: | CE, RoHS |

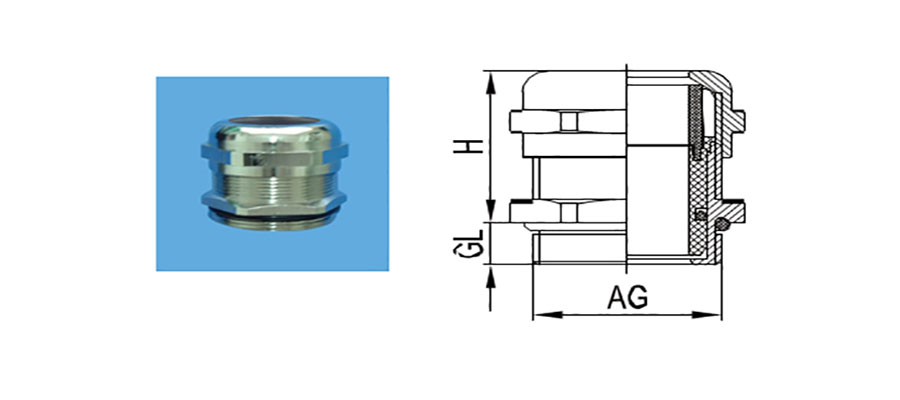

Specification

(Please contact us for more information if you need other sizes or threads not included in the following list.)

|

Article no. |

Thread |

Clamping range |

AG |

GL |

(H) |

Wrench size |

Packet |

|

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

HSM-EMV-M12 |

M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

|

HSM-EMV-M16 |

M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

|

HSM-EMV-M18 |

M18×1.5 |

5~10 |

18 |

7 |

22.5 |

20/20 |

50 |

|

HSM-EMV-M20 |

M20×1.5 |

6~12 |

20 |

7 |

25 |

22/22 |

32 |

|

HSM-EMV-M24 |

M24×1.5 |

8~14 |

24 |

7 |

24 |

24/27 |

18 |

|

HSM-EMV-M25 |

M25×1.5 |

10~16 |

25 |

7 |

25.5 |

28/28 |

18 |

|

HSM-EMV-M25-D |

M25×1.5 |

13~18 |

25 |

7 |

27 |

30/30 |

18 |

|

HSM-EMV-M30 |

M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

|

HSM-EMV-M32 |

M32×1.5 |

15~22 |

32 |

8 |

29 |

36/36 |

18 |

|

HSM-EMV-M32-D |

M32×1.5 |

18~25 |

32 |

8 |

34.5 |

40/38 |

8 |

|

HSM-EMV-M36 |

M36×2.0 |

18~25 |

36 |

8 |

34.5 |

40/40 |

8 |

|

HSM-EMV-M40 |

M40×1.5 |

22~30 |

40 |

9 |

37.5 |

45/45 |

4 |

|

HSM-EMV-M40-D |

M40×1.5 |

22~32 |

40 |

9 |

40 |

50/50 |

4 |

|

HSM-EMV-M48 |

M48×2.0 |

22~32 |

48 |

9 |

40 |

50/52 |

4 |

|

HSM-EMV-M50 |

M50×1.5 |

30~38 |

50 |

9 |

42 |

58/55 |

2 |

|

HSM-EMV-M56 |

M56×2.0 |

30~38 |

56 |

9 |

41 |

60/58 |

2 |

|

HSM-EMV-M63 |

M63×1.5 |

37~44 |

63 |

10 |

42.5 |

65/70 |

2 |

|

HSM-EMV-M64 |

M64×2.0 |

37~44 |

64 |

10 |

42.5 |

65/70 |

2 |

|

|

|

|

|

|

|

|

|

|

HSM-EMV-P07 |

PG7 |

3~6.5 |

12.5 |

6 |

20 |

14/14 |

75 |

|

HSM-EMV-P09 |

PG9 |

4~8 |

15.2 |

7 |

21 |

17/17 |

75 |

|

HSM-EMV-P11 |

PG11 |

5~10 |

18.6 |

7 |

23.5 |

20/20 |

32 |

|

HSM-EMV-P13.5 |

PG13.5 |

6~12 |

20.4 |

7 |

25 |

22/22 |

32 |

|

HSM-EMV-P16 |

PG16 |

8~14 |

22.5 |

7 |

24 |

24/24 |

32 |

|

HSM-EMV-P21 |

PG21 |

13~18 |

28.3 |

8 |

27 |

30/30 |

18 |

|

HSM-EMV-P29 |

PG29 |

18~25 |

37 |

8 |

34.5 |

40/40 |

8 |

|

HSM-EMV-P36 |

PG36 |

22~32 |

47 |

9 |

40 |

50/50 |

4 |

|

HSM-EMV-P42 |

PG42 |

30~38 |

54 |

9 |

42 |

58/58 |

2 |

|

HSM-EMV-P48 |

PG48 |

37~44 |

59.3 |

10 |

42.5 |

65/65 |

2 |

Application

Do away with one small section of the outer sheath of the screened cable, and cut off the shield layer, turn over the conductor of the shield layer and wrap it outside the seal, the length of it should be longer than the position of the sealing ring, then put into the cable gland and revolve it tightly.

We suggest scraping the paint contacted to the cable gland and the thread to guarantee the good electric conductivity.