Chinese Professional Ss 316 Cable Gland - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer

Chinese Professional Ss 316 Cable Gland - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer Detail:

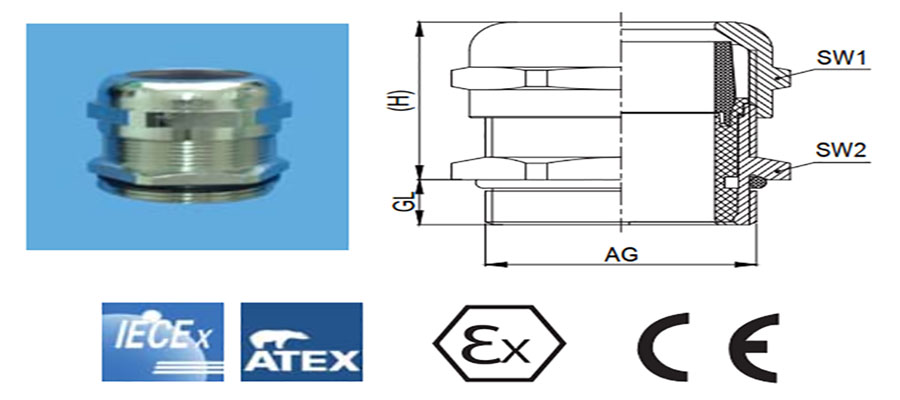

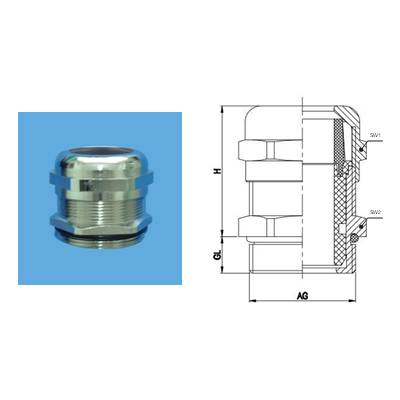

Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread)

Introduction

Cable glands are mainly used to clamp, fix, protect the cables from water and dust. They are widely applied to such fields as control boards, apparatuses, lights, mechanical equipment, train, motors, projects etc.We can provide you with metal cable glands made of nickel-plated brass (Order No.: HSM-EX) and stainless steel (Order No.: HSMS-EX).

| Material: | Body: nickel-plated brass; seal: polyamide; sealing: modified rubber |

| Temperature Range: | Min -40℃, Max 100℃, Short-term 120℃ |

| Protection degree: | IP68(IEC60529) with suitable O-ring within specified clamping range |

| Properties: | Resistance to vibration and impact, in accordance with IEC-60077-1999. |

| Applications: | Machine building, electric equipment, electric control cupboard |

| Certifications: | CE, RoHS, Exe II Gb, IECEx, ATEX. |

Specification

(Please contact us for more information if you need other sizes not included in the following list.)

|

Explosion-proof Nickel-plated brass cable gland (Metric thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-M12 |

M12×1.5 |

3~6.5 |

12 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-M16-H |

M16×1.5 |

3~6.5 |

16 |

7 |

20 |

14/18 |

75 |

|

HSM-EX-M16 |

M16×1.5 |

4~8 |

16 |

7 |

21 |

17/18 |

75 |

|

HSM-EX-M16-D |

M16×1.5 |

5~10 |

16 |

7 |

22.5 |

20/20 |

32 |

|

HSM-EX-M18 |

M18×1.5 |

5~10 |

18 |

7 |

22.5 |

20/20 |

50 |

|

HSM-EX-M20-H |

M20×1.5 |

5~10 |

20 |

7 |

22.5 |

20/22 |

32 |

|

HSM-EX-M20 |

M20×1.5 |

6~12 |

20 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-M20-D |

M20×1.5 |

8~14 |

20 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M22 |

M22×1.5 |

8~14 |

22 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-M24-H |

M24×1.5 |

6~12 |

24 |

7 |

23.5 |

24/27 |

18 |

|

HSM-EX-M24 |

M24×1.5 |

8~14 |

24 |

7 |

23 |

24/27 |

18 |

|

HSM-EX-M25-H |

M25×1.5 |

8~14 |

25 |

7 |

23 |

24/28 |

18 |

|

HSM-EX-M25 |

M25×1.5 |

10~16 |

25 |

7 |

24.5 |

28/28 |

18 |

|

HSM-EX-M25-D |

M25×1.5 |

13~18 |

25 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-M27-H |

M27×2.0 |

10~16 |

27 |

8 |

24.5 |

28/30 |

18 |

|

HSM-EX-M27 |

M27×2.0 |

13~18 |

27 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-M30-H |

M30×2.0 |

10~16 |

30 |

8 |

24.5 |

28/34 |

18 |

|

HSM-EX-M30 |

M30×2.0 |

13~18 |

30 |

8 |

26 |

30/34 |

18 |

|

HSM-EX-M32-H |

M32×1.5 |

13~18 |

32 |

8 |

26 |

30/36 |

8 |

|

HSM-EX-M32 |

M32×1.5 |

15~22 |

32 |

8 |

28 |

36/36 |

18 |

|

HSM-EX-M32-D |

M32×1.5 |

18~25 |

32 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M33 |

M33×2.0 |

18~25 |

33 |

8 |

33 |

40/38 |

8 |

|

HSM-EX-M36-H |

M36×2.0 |

15~22 |

36 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-M36 |

M36×2.0 |

18~25 |

36 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-M40-H |

M40×1.5 |

18~25 |

40 |

9 |

33.5 |

40/45 |

8 |

|

HSM-EX-M40 |

M40×1.5 |

22~30 |

40 |

9 |

35.5 |

45/45 |

8 |

|

HSM-EX-M40-D |

M40×1.5 |

22~32 |

40 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M42 |

M42×2.0 |

22~32 |

42 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-M48 |

M48×2.0 |

22~32 |

48 |

9 |

38.5 |

50/52 |

4 |

|

HSM-EX-M50 |

M50×1.5 |

30~38 |

50 |

9 |

40 |

58/55 |

4 |

|

HSM-EX-M56 |

M56×2.0 |

30~38 |

56 |

9 |

40 |

58/60 |

2 |

|

HSM-EX-M60 |

M60×2.0 |

37~44 |

60 |

10 |

41 |

65/65 |

2 |

|

HSM-EX-M63 |

M63×1.5 |

37~44 |

63 |

10 |

41 |

65/70 |

2 |

|

HSM-EX-M63-D |

M63×1.5 |

42~53 |

63 |

10 |

44.5 |

75/75 |

2 |

|

HSM-EX-M64 |

M64×2.0 |

37~44 |

64 |

10 |

41 |

65/70 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07 |

PG7 |

3~6.5 |

12.5 |

6 |

19 |

14/14 |

75 |

|

HSM-EX-P09-H |

PG9 |

3~6.5 |

15.2 |

7 |

20 |

14/17 |

75 |

|

HSM-EX-P09 |

PG9 |

4~8 |

15.2 |

7 |

21 |

17/17 |

75 |

|

HSM-EX-P11 |

PG11 |

5~10 |

18.6 |

7 |

22.5 |

20/22 |

75 |

|

HSM-EX-P13.5-H |

PG13.5 |

5~10 |

20.4 |

7 |

22.5 |

22/22 |

32 |

|

HSM-EX-P13.5 |

PG13.5 |

6~12 |

20.4 |

7 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-H |

PG16 |

6~12 |

22.5 |

7 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16 |

PG16 |

8~14 |

22.5 |

7 |

23 |

24/24 |

32 |

|

HSM-EX-P21-H |

PG21 |

10~16 |

28.3 |

7 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21 |

PG21 |

13~18 |

28.3 |

7 |

26 |

30/30 |

18 |

|

HSM-EX-P29-H |

PG29 |

15~22 |

37 |

8 |

28 |

36/40 |

8 |

|

HSM-EX-P29 |

PG29 |

18~25 |

37 |

8 |

33 |

40/40 |

8 |

|

HSM-EX-P36 |

PG36 |

22~32 |

47 |

9 |

38.5 |

50/50 |

4 |

|

HSM-EX-P42 |

PG42 |

30~38 |

54 |

9 |

40 |

58/58 |

2 |

|

HSM-EX-P48 |

PG48 |

37~44 |

59.3 |

10 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (PG thread: lengthened thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-P07-L |

PG7 |

3~6.5 |

12.5 |

10 |

19 |

14/14 |

50 |

|

HSM-EX-P09-HL |

PG9 |

3~6.5 |

15.2 |

10 |

20 |

14/17 |

50 |

|

HSM-EX-P09-L |

PG9 |

4~8 |

15.2 |

10 |

21 |

17/17 |

50 |

|

HSM-EX-P11-L |

PG11 |

5~10 |

18.6 |

10 |

22.5 |

20/20 |

50 |

|

HSM-EX-P13.5-HL |

PG13.5 |

5~10 |

20.4 |

10 |

22.5 |

20/22 |

32 |

|

HSM-EX-P13.5-L |

PG13.5 |

6~12 |

20.4 |

10 |

23.5 |

22/22 |

32 |

|

HSM-EX-P16-HL |

PG16 |

6~12 |

22.5 |

10 |

23.5 |

22/24 |

32 |

|

HSM-EX-P16-L |

PG16 |

8~14 |

22.5 |

10 |

23 |

24/24 |

32 |

|

HSM-EX-P21-HL |

PG21 |

10~16 |

28.3 |

12 |

24.5 |

28/30 |

18 |

|

HSM-EX-P21-L |

PG21 |

13~18 |

28.3 |

12 |

26 |

30/30 |

18 |

|

HSM-EX-P29-HL |

PG29 |

15~22 |

37 |

12 |

28 |

36/40 |

8 |

|

HSM-EX-P29-L |

PG29 |

18~25 |

37 |

12 |

33 |

40/40 |

8 |

|

HSM-EX-P36-L |

PG36 |

22~32 |

47 |

15 |

38.5 |

50/50 |

2 |

|

HSM-EX-P42-L |

PG42 |

30~38 |

54 |

15 |

40 |

58/58 |

2 |

|

HSM-EX-P48-L |

PG48 |

37~44 |

59.3 |

15 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (G thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-G3/8 |

G3/8″ |

4~8 |

16.66 |

8 |

21 |

17/20 |

32 |

|

HSM-EX-G1/2-H |

G1/2″ |

5~10 |

20.99 |

8 |

22.5 |

20/24 |

32 |

|

HSM-EX-G1/2 |

G1/2″ |

6~12 |

20.99 |

8 |

23.5 |

22/24 |

32 |

|

HSM-EX-G1/2-D |

G1/2″ |

8~14 |

20.99 |

8 |

23.5 |

24/24 |

32 |

|

HSM-EX-G3/4-TH |

G3/4″ |

6~12 |

26.44 |

8 |

23.5 |

22/30 |

18 |

|

HSM-EX-G3/4-H |

G3/4″ |

8~14 |

26.44 |

8 |

23.5 |

24/30 |

18 |

|

HSM-EX-G3/4 |

G3/4″ |

13~18 |

26.44 |

8 |

26 |

30/30 |

18 |

|

HSM-EX-G1 |

G1″ |

18~25 |

33.24 |

9 |

33 |

40/40 |

8 |

|

HSM-EX-G1 1/4 |

G1 1/4″ |

22~32 |

41.91 |

10 |

38.5 |

50/50 |

4 |

|

HSM-EX-G1 1/2 |

G1 1/2″ |

30~38 |

47.8 |

10 |

40 |

58/55 |

2 |

|

HSM-EX-G2 |

G2″ |

37~44 |

59.61 |

11 |

41 |

65/65 |

2 |

|

Explosion-proof Nickel-plated brass cable gland (NPT thread) |

|||||||

|

Article no. |

Thread |

Hole size |

AG |

GL |

H |

SW1/SW2 |

Packet |

|

Dimension |

mm |

mm |

mm |

mm |

mm |

units |

|

|

HSM-EX-N3/8 |

NPT3/8 |

4~8 |

16.65 |

16 |

21 |

17/20 |

32 |

|

HSM-EX-N1/2-H |

NPT1/2″ |

5~10 |

21.85 |

20 |

22.5 |

20/23 |

32 |

|

HSM-EX-N1/2 |

NPT1/2″ |

6~12 |

21.85 |

20 |

23.5 |

22/23 |

32 |

|

HSM-EX-N1/2-D |

NPT1/2″ |

8~14 |

21.85 |

20 |

23.5 |

24/24 |

32 |

|

HSM-EX-N3/4-TH |

NPT3/4″ |

6~12 |

26.3 |

21 |

23.5 |

22/30 |

18 |

|

HSM-EX-N3/4-H |

NPT3/4″ |

8~14 |

26.3 |

21 |

23 |

24/30 |

18 |

|

HSM-EX-N3/4 |

NPT3/4″ |

13~18 |

26.3 |

21 |

26 |

30/30 |

18 |

|

HSM-EX-N1 |

NPT1″ |

18~25 |

33.15 |

26 |

33 |

40/40 |

8 |

|

HSM-EX-N1 1/4 |

NPT1 1/4″ |

22~32 |

41.85 |

26 |

38.5 |

50/50 |

4 |

|

HSM-EX-N1 1/2 |

NPT1 1/2″ |

30~38 |

47.75 |

27 |

40 |

58/55 |

2 |

|

HSM-EX-N2 |

NPT2″ |

37~44 |

59.55 |

27 |

41 |

65/65 |

2 |

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Chinese Professional Ss 316 Cable Gland - Explosion-proof Metal Cable Gland (Metric/PG/NPT/G thread) – Weyer, The product will supply to all over the world, such as: Mali, Montreal, Egypt, If you need to have any of our merchandise, or have other items to be produced, make sure you send us your inquiries, samples or in depth drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!