2020 China New Design Flex Conduit Connectors - Polyamide Corrugated Tubing – Weyer

2020 China New Design Flex Conduit Connectors - Polyamide Corrugated Tubing – Weyer Detail:

Introduction of Polyamide 6 Tubing

Nylon tubing (polyamide), referred to as PA tubing. It is a kind of synthetic fiber, with good physical and chemical and mechanical properties: abrasion resistance, can be used in the condition of sand, iron scraps; smooth surface, reduce resistance, can prevent rust and scale deposition; soft, easy it is curved, easy to install and easy to process. At the same time, it is steel. When a certain shape is needed, it can be made into a variety of shapes like a metal tube, and it does not require complicated equipment and tooling; it can withstand the corrosion of many chemical substances; it has stable dimensions and small permeability; Can be used as an insulator; the service life is very long, even for decades; good temperature resistance, can work in the environment of -40-115 ° C.

WYK-PA6

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Flame-retardant | HB (UL94), according to FMVSS 302: <100mm/min |

| Properties | Flexible and excellent tenacity, medium wall thickness, glossySurface, wind resistant, high mechanical strength, resistant to oil, acid and alkali. Anti-friction, black tubings are UV-resistant, Free of Halogen, phosphor and cadmium, passed RoHS. Ultra flat inner hole, less abrasion to the cables |

| Applications | Mechanical building, electric insulation protection, underground, electric vehicle and air-conditioner equipment etc.Especially suitable for vehicle industry with frequent vibration |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-UFW-PA | G/B | (mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/ring) |

| *WY-UFW-PA6-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-PA6-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6-AD13.0G | Grey | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-UFW-PA6-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-PA6-AD21.2G | Grey | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6-AD25.5G | Grey | 19.5×25.5 | 42 | 85 | 0.054 | 50 |

| WY-UFW-PA6-AD28.5G | Grey | 22.2×28.5 | 45 | 100 | 0.081 | 50 |

| WY-UFW-PA6-AD31.5G | Grey | 25.0×31.5 | 50 | 110 | 0.095 | 25 |

| *WY-UFW-PA6-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.108 | 25 |

| *WY-UFW-PA6-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| *WY-UFW-PA6-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.207 | 25 |

| WY-UFW-PA6-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-PA6-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6-AD13.0B | Black | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-UFW-PA6-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-PA6-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6-AD25.5B | Black | 19.5×25.5 | 42 | 85 | 0.054 | 50 |

| WY-UFW-PA6-AD28.5B | Black | 22.2×28.5 | 45 | 100 | 0.081 | 50 |

| WY-UFW-PA6-AD31.5B | Black | 25.0×31.5 | 50 | 110 | 0.095 | 25 |

| WY-UFW-PA6-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.108 | 25 |

| WY-UFW-PA6-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| WY-UFW-PA6-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.207 | 25 |

| WY-UFW-PA6/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-PA6/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6/S-AD13.0B | Slit Black | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.032 | 100 |

| WY-UFW-PA6/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-PA6 /S-AD21.2B | Slit Black | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6/S-AD25.5B | Slit Black | 19.5×25.5 | 42 | 85 | 0.054 | 50 |

| WY-UFW-PA6/S-AD28.5B | Slit Black | 22.2×28.5 | 45 | 100 | 0.081 | 50 |

| WY-UFW-PA6/S-AD31.5B | Slit Black | 25.0×31.5 | 50 | 110 | 0.095 | 25 |

| WY-UFW-PA6/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.108 | 25 |

| WY-UFW-PA6/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| WY-UFW-PA6/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.207 | 25 |

WY-UFW-FPA6

| Material | Polyamide 6 |

| Color | Grey (RAL 7037), black (RAL 9005) |

| Temperature Range | Min-40℃,Max125℃,Short-term150℃ |

| Flame-retardant | V0(UL94), self-extinguishing, A level, according to FMVSS 302requirements, according to GB/T2408 standard, flame retardant to V0 level |

| Properties | Flexible and excellent tenacity, medium wall thickness, glossySurface, wind resistant, high mechanical strength, resistant to oil, acid and alkali. Anti-friction, black tubings are UV-resistant, Free of Halogen, phosphor and cadmium, passed RoHS. Ultra flat inner hole, less abrasion to the cables |

| Applications | Mechanical building, electric insulation protection, underground, electric vehicle and air-conditioner equipment etc.Especially suitable for vehicle industry with frequent vibration |

| Fit with | All Tubing connectors except WYTC open connectors |

Tech Specification

| Article no. | Color | ID×OD | Stat.R | Dyn.R | Weight | PU |

| WY-UFW-FPA6 | G/B | (mm×mm) | (mm) | (mm) | Dyn.r(mm) | (kg/m±10%) |

| *WY-UFW-FPA6-AD8.0G | Grey | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-FPA6-AD10.0G | Grey | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6-AD13.0G | Grey | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6-AD15.8G | Grey | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6-AD18.5G | Grey | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-FPA6-AD21.2G | Grey | 16.0×21.2 | 40 | 75 | 0.055 | 50 |

| WY-UFW-FPA6-AD25.5G | Grey | 19.5×25.5 | 42 | 85 | 0.059 | 50 |

| WY-UFW-FPA6-AD28.5G | Grey | 22.2×28.5 | 45 | 100 | 0.086 | 50 |

| WY-UFW-FPA6-AD31.5G | Grey | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| *WY-UFW-FPA6-AD34.5G | Grey | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| *WY-UFW-FPA6-AD42.5G | Grey | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| *WY-UFW-FPA6-AD54.5G | Grey | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

| WY-UFW-FPA6-AD8.0B | Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-FPA6-AD10.0B | Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6-AD13.0B | Black | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6-AD15.8B | Black | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6-AD18.5B | Black | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-FPA6-AD21.2B | Black | 16.0×21.2 | 40 | 75 | 0.055 | 50 |

| WY-UFW-FPA6-AD25.5B | Black | 19.5×25.5 | 42 | 85 | 0.059 | 50 |

| WY-UFW-FPA6-AD28.5B | Black | 22.2×28.5 | 45 | 100 | 0.086 | 50 |

| WY-UFW-FPA6-AD31.5B | Black | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| WY-UFW-FPA6-AD34.5B | Black | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| WY-UFW-FPA6-AD42.5B | Black | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| WY-UFW-FPA6-AD54.5B | Black | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

| WY-UFW-FPA6/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-FPA6/S-AD13.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6/S-AD10.0B | Slit Black | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.045 | 50 |

| WY-UFW-FPA6/S-AD21.2B | Slit Black | 16.0×21.2 | 40 | 75 | 0.055 | 50 |

| WY-UFW-FPA6/S-AD25.5B | Slit Black | 19.5×25.5 | 42 | 85 | 0.059 | 50 |

| WY-UFW-FPA6/S-AD31.5B | Slit Black | 22.2×28.5 | 45 | 100 | 0.086 | 50 |

| WY-UFW-FPA6 /S-AD28.5B | Slit Black | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| WY-UFW-FPA6/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| WY-UFW-FPA6/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| WY-UFW-FPA6/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

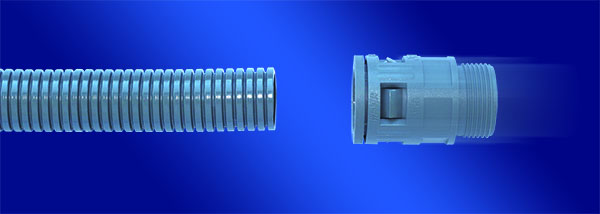

Installation instructions of Polyamide Tubing

Pushing the tubing into the connector and its assembly is done. Push again until it can not complete its fixing so that it can reach some protection degree.

Normal wave

Ultra flat wave

Non-slit tubing

Slit tubing

Advantages of Flexible Polyamide Conduit

1. High mechanical strength, good toughness, high tensile and compressive strength.

2. The fatigue resistance is outstanding, and the parts can still maintain the original mechanical strength after repeated bending.

3. High softening point and heat resistance.

4. The surface is smooth, the friction coefficient is small, and it is wear-resistant.

5. Corrosion resistance.

6. Self-extinguishing, non-toxic, odorless.

7. Excellent electrical properties, good electrical insulation.

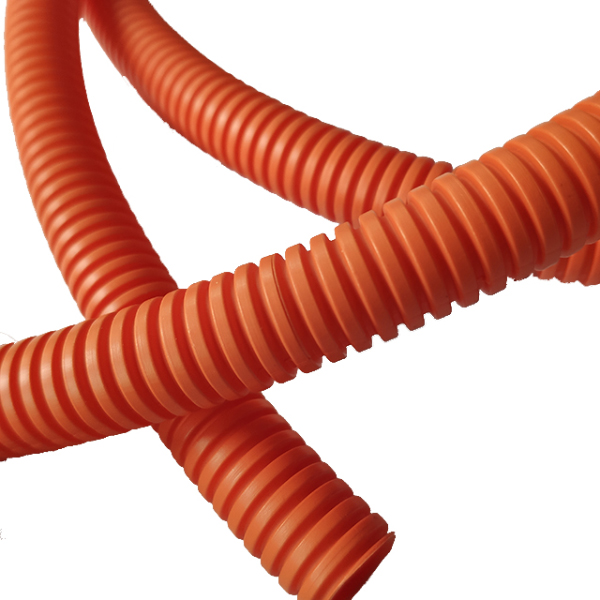

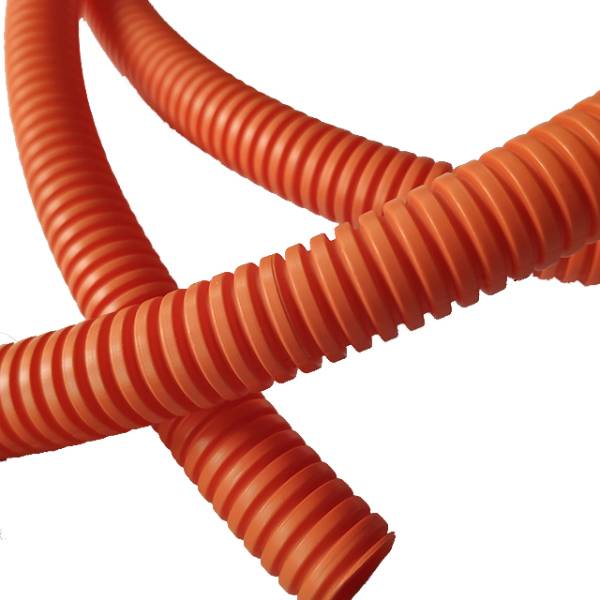

Pictures of Corrugated Polyamide Tubing

Application PolyamideTubing: Machine building

Below photos we are sharing for application used in one of our customer in machinery. The cables need to be protected under IP68 or IP69K against the water and dust when coming out of the control box, which can extend the life of cable usage.

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for 2020 China New Design Flex Conduit Connectors - Polyamide Corrugated Tubing – Weyer, The product will supply to all over the world, such as: Paraguay, Kuala Lumpur, Russia, With excellent solutions, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We'll satisfy you with our qualified service!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!